Engineering Data

Noise Reduction Data

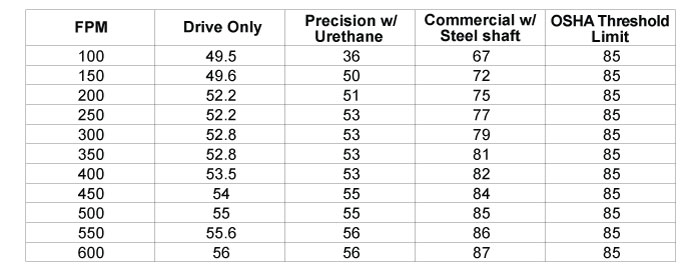

The table below gives a comparison between stamped commercial bearings with standard steel shafts and precision bearings with urethane shaft adapters. An electric motor mounted under a bed of 6 rollers with urethane "O" rings was used for the drive. The frame was a standard 7/16" hex punched unit on 3" centers. Speeds from 100-600 FPM were tested. The noise generated from the drive itself was measured and recorded first. Rollers were then added and the noise level measured again with the drive included. Motor noise was then backed out to reflect only the noise generated by the rollers. Results were recorded using the A scale of the decibel meter. The rollers used for the test are described as follows:

Precision with Urethane Shaft Adapters:

Tube: Galvanized 1.9” diameter x .065” wall thickness; grooved

for 3/16” urethane “O” rings

Bearings: ABEC-1 precision ball bearing with C3 clearance in a conductive

plastic housing

Shaft: 7/16” hex urethane adapters with a 5/16” hex internal

steel support shaft

Commercial with Carbon Steel Shaft:

Tube: Galvanized 1.9” diameter x .065” wall thickness; grooved

for 3/16” urethane “O” rings

Bearings: Stamped zinc plated commercial

Shaft: 7/16” hex carbon steel shaft

Results vary with different types of drives, varying types of building construction and proximity of conveyor to walls as examples. In every test conducted in a controlled atmosphere, precision rollers with urethane shaft adapters have reduced noise levels a minimum of 9 decibels.

Your results may vary depending on a variety of variables unrelated to the roller. This data is offered as an example and guideline only.